The below error codes are for chigo DC inverter multi-split series, inverter single split series, portable air conditioner serial, floor standing AC serial and wall split AC series. We also offering you the solution and how to troubleshoot after you know the error code.

Chigo wall split AC series error codes

| Error code | Failure | Check Procedure |

|---|---|---|

| DF | anti cold wind | 1. Normal (during heating mode ) 2. It will be removed when the coil pipe temperature sensor reaches certain temperature. |

| E2 | room temp sensor fault | 1. Check whether the resistance of the sensor is normal (the resistance is 5КΩ in the normal temperature 25 ) ℃ , when it is abnormal the sensor should be replaced. 2. Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced. |

| E3 | room temp sensor fault | 1. Check whether the resistance of the sensor is normal (the resistance is 5КΩ in the normal temperature 25 ) ℃ , when it is abnormal the sensor should be replaced. 2. Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced |

| E4 | outdoor unit abnormal | 1. Check whether the winding resistance and operation current of the compressor are normal. 2、Check whether the high and low pressure is normal when the unit is running. 3、Check (whether the coil pipe sensor is normal) whether the contact of the inserter on the circuit board is well, the coil pipe temperature sensor is fixed, the evaporation of the indoor unit is well, the key is to check the evaporator temperature detected by the coil pipe temperature sensor has reached the cooling or heating temperature. 4、Check whether the surface of the condenser is too dirty, it should be cleaned when it is too dirty. 5、Check whether the capacitance of the outdoor motor and the fan is damaged, it should be replaced when 3 it is damaged. 6、If the above items are normal, the electric control board should be replaced. |

| E5 | no feedback signal of indoor fan | 1. Check whether two sets of plugs on the outlet end of the motor have loosed from the socket of the electric control board, insert it firmly when loosing. 2. Check whether the indoor motor has damaged, the motor should be replaced when it is damaged 3. Check whether the controllable silicon and other components on the electric control board have damaged, replace the controllable silicon or electric control board when they are damaged |

| E6 | no over zero signal | 1. Firstly check whether the indoor fan is normal. 2. Check whether the signal outputting from the integrated chip of the electric control board is normal, the electric control board should be replaced when the signal is abnormal. |

| E7 | outdoor feedback fault | 1. Check whether the winding resistance and operation current of the compressor are normal 2. Check whether the high and low pressure is normal when the unit is running. 3. Check whether the indoor and outdoor wiring is right; when it is wrong, connect them again according to the circuit diagram 4. Check whether the contact of the inserter on the circuit board and the connection are well, otherwise repair. 5. Check whether the signal feedback wire is disconnected, replace or connect the feedback signal wire. 6. Check whether the supply power is phase-lacking or phase opposition. 7. Check whether the AC electromagnetic contactor is well |

| E8 | frost protection/over heat protection | 1. Check whether the filter of the indoor unit is dirty or blocked, and clean if it is dirty. 2. Check whether the indoor fan is running normally, and replace the motor if it is abnormal. 3. Check whether indoor pipe temperature sensor is normal, and replace the sensor if it is abnormal. 4. Check whether the system pressure is normal, if abnormal, should check whether there is leakage, and fill the refrigerant again |

Chigo floor standing AC error codes

| Error code | Failure | Check Procedure |

|---|---|---|

| E2 | room temp sensor fault | 1. Check whether the resistance of the sensor is normal (the resistance is 5КΩ in the normal temperature 25 ) ℃ , when it is abnormal the sensor should be replaced. 2. Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced |

| E3 | room temp sensor fault | 1. Check whether the resistance of the sensor is normal (the resistance is 5КΩ in the normal temperature 25 ) ℃ , when it is abnormal the sensor should be replaced. 2. Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced. |

| E4 | outdoor unit abnormal | 1. Check whether the winding resistance and operation current of the compressor are normal. 2. Check whether the high and low pressure is normal when the unit is running. 3. Check (whether the coil pipe sensor is normal) whether the contact of the inserter on the circuit board is well, the coil pipe temperature sensor is fixed, the evaporation of the indoor unit is well, the key is to check the evaporator temperature detected by the coil pipe temperature sensor has reached the cooling or heating temperature. 4. Check whether the surface of the condenser is too dirty, it should be cleaned when it is too dirty. 5. Check whether the capacitance of the outdoor motor and the fan is damaged, it should be replaced when it is damaged. 6. If the above items are normal, the electric control board should be replaced. |

| E7 | outdoor feedback fault | 1. Check whether the winding resistance and operation current of the compressor are normal 2. Check whether the high and low pressure is normal when 5 the unit is running. 3. Check whether the indoor and outdoor wiring is right; when it is wrong, connect them again according to the circuit diagram 4. Check whether the contact of the inserter on the circuit board and the connection are well, otherwise repair. 5. Check whether the signal feedback wire is disconnected, replace or connect the feedback signal wire. 6. Check whether the supply power is phase-lacking or phase opposition. 7. Check whether the AC electromagnetic contactor is well |

| E8 | frost protection /over heat protection | 1. Check whether the filter of the indoor unit is dirty or blocked, and clean if it is dirty. 2. Check whether the indoor fan is running normally, and replace the motor if it is abnormal. 3. Check whether indoor pipe temperature sensor is normal, and replace the sensor if it is abnormal. 4. Check whether the system pressure is normal, if abnormal, should check whether there is leakage, and fill the refrigerant again. |

Chigo portable air conditioner error codes

| Error code | Failure | Check Procedure |

|---|---|---|

| E2 | room temp sensor fault | 1. Check whether the resistance of the sensor is normal (the resistance is 5КΩ in the normal temperature 25 ) ℃ , when it is abnormal the sensor should be replaced. 2. Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced |

| E3 | coil temp sensor fault | 1. Check whether the resistance of the sensor is normal (the resistance is 5КΩ in the normal temperature 25 ) ℃ , when it is abnormal the sensor should be replaced. 2. Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired. 3. When the 1 and 2 are both normal, then the 6 components or integrated circuit is damaged, the electric control board should be replaced |

| E4 | abnormal protection | 1. Check whether the operation current and power of the unit is abnormal. 2. Check whether the speed and wind quantity of the fan is normal, otherwise replace the outdoor fan or capacitance 3. Check whether the surface of the condenser is too dirty, and it should be cleaned when it is too dirty. 4. Check whether the unit is short of the refrigerant, add the refrigerant after leakage detection and repair welding. 5. Check whether the sensor and electric control board is normal, otherwise replace the board. |

| E5 | water level over limit | 1. Normal, discharge the water out, it will return to normal condition automatically 2. Check the water level switch, and replace it when fault. |

| E8 | over heat protection(PTC temp. ≥ 152 ℃) | 1. Check whether the fan is normal, otherwise replace corresponding motor or capacitance. 2. Check the resistance of the electric heater is normal, otherwise replace it. |

Chigo inverter single split series aircon error codes

| Error code | Failure | Check Procedure |

|---|---|---|

| F1 | communication fault | 1. Check whether the connection of the outdoor unit and indoor unit is one to one, otherwise connect the L, N and communication line of the indoor unit and outdoor unit one to one. 2. Measure whether the voltage between the zero line and the communication line is 18V-30AC half-wave signal, check whether the communication circuit on the indoor and outdoor electric control board has been damaged, otherwise replace it. 3. Check whether the LED on the outdoor power board has been on, otherwise replace the electric control board. 4. Check whether the unit is abnormal caused by the external interference, if it is, then find the interfering source, and removes it |

| F2 | ambient temp sensor fault | 1. Check whether the resistance of sensor is normal, otherwise replace it. 2. Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced. |

| F3 | coil pipe temp. sensor of indoor unit fault(inlet,middle ,outlet) | 1. Check whether the resistance of sensor is normal, otherwise replace it. 2. Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced. |

| F4 | fan motor of indoor unit fault | 1. Check whether the contact of the plug of the motor wire and socket is well, making sure well contact. 2、Check whether the indoor motor has damaged, the motor should be replaced when it is damaged. 3、Check whether the controllable silicon and other components on the electric control board have damaged, replace the controllable silicon or electric control board when they are damaged. |

| F5 | module of outdoor unit fault | 1. Check whether the connection of the compressor is reliable, otherwise connect firmly again. 2. Check whether the fixation between the IPM module and the radiator is firm. 3. Check whether the compressor is well, otherwise replace it. 4. Check whether the IPM module is abnormal, otherwise replace it |

| F6 | ambient temp. sensor of outdoor fault | 1. Check whether the resistance of sensor is normal, otherwise replace it. 2. Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced |

| F7 | coil pipe temp. sensor of outdoor unit fault | 1. Check whether the resistance of sensor is normal, otherwise replace it. 2. Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced. |

| F8 | suction temp. sensor of compressor fault | 1. Check whether the resistance of sensor is normal, otherwise replace it. 2. Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced. |

| F9 | discharge temp. sensor of compressor fault | 1. Check whether the resistance of sensor is normal, otherwise replace it. 2. Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control 9 board, repair it if there is any above. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced. |

| FA | inductor of current or voltage fault | Check whether inductor of current or voltage have been damaged, they should be replaced if they are fault. |

| FC | compressor drive fault | 1. Power on again, and check the operation of the compressor is normal. 2. Check whether the connection of the compressor is reliable, otherwise repair. 3. Check whether the components on the electric control board have been damaged, if they are damaged, the components or the electric control board should be replaced |

| FD | phase lacking or phase sequence fault | Check power wire voltage or change two power wires |

| FE | gas return sensor fault(include A,B,C,D) | 1. Check whether the resistance of sensor is normal, otherwise replace it. 2. Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced. |

| P1 | temp. of evaporator protection | 1. Check whether the filter of indoor unit is too dirty, and it should be cleaned when it is too dirty. 2. Check whether it has barrier around indoor unit, it should be remove if it has. 3. Check whether the indoor motor is damaged, it should be replaced motor or electrical control board when it is damaged. |

| P2 | overheat, over current protection of inverter module | 1. Check whether the fixation between the IPM module and the radiator is firm. 2. Check whether the compressor is well, otherwise replace it. 3. Check whether the IPM module is abnormal, otherwise replace it. |

| P3 | over current protection | 1. Check whether the ambient temperature exceeds the operation range for the air conditioner 2. Check whether the current detection circuit is abnormal, the electric control should be replaced when it is abnormal. |

| P4 | discharge temp. of compressor | 1. Check whether the air condition system and pressure are normal. 2. Check whether the sensor, connecting wire of the sensor and the detection circuit are abnormal |

| P5 | over heat of compressor top protection | 1. Check whether the air condition system and pressure are normal. 2. Check whether the sensor, connecting wire of the sensor and the detection circuit are abnormal. |

| P6 | suction temp. of compressor protection | 1. Check whether the air condition system and pressure are normal. 2. Check whether the sensor, connecting wire of the sensor and the detection circuit are abnormal. |

| P7 | low or high voltage protection | 1. Check whether the supply voltage is out of rang from 150 to 270V 2. Check the voltage detection circuit of the IPM base board is abnormal, if it is abnormal, the IPM base board or the electric control board should be replaced. |

| P8 | low presser of gas return protection | Check whether the pressure is normal when the unit is running, if it is abnormal, should detect the leakage and welding, add refrigerant |

| P9 | high pressure of discharge protection | Check whether the pressure is normal when the unit is running, if it is abnormal, should detect the leakage and welding, add refrigerant |

| PA | high temp. of condenser protection | 1. Check whether the condenser of outdoor unit is too dirty, and it should be cleaned when it is too dirty. 2. Check whether it is running at bad condition long time. 3. Check whether senor and wire are normal. |

| PC | high temp. of outdoor ambient protection | 1. Check the outdoor ambient temperature is too high or there is heat source around the outdoor unit. 2. Check whether the sensor and sensor wire are normal. |

Chigo DC inverter multi-split series aircon error codes

| Error code | Failure | Check Procedure |

|---|---|---|

| F1 | communicate fault | 1. Check whether the connection of the outdoor unit and indoor unit is one to one. 2. Check whether the unit is abnormal caused by the external interference, if it is, then find the interfering source, and removes it. 3. Check whether the electrical control board is damage, it should be replaced when it is damaged. |

| F2 | indoor temp sensor fault | 1. Check whether the resistance of sensor is normal, otherwise replace it. 2. Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced |

| F3 | outlet e temp. sensor of indoor unit coil pipe fault | 1. Check whether the resistance of sensor is normal, otherwise replace it. 2. Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced. |

| F4 | PG motor fault | 1. Check whether the contact of the plug of the motor wire and socket is well, making sure well contact. 2. Check whether the indoor motor has damaged, the motor should be replaced when it is damaged. 3. Check whether the controllable silicon and other components on the electric control board have damaged, replace the controllable silicon or electric control board when they are damaged |

| P2 | protection of module fault | 1. Check whether the connection of the compressor is reliable, otherwise connect firmly again. 2. Check whether the fixation between the IPM module and the radiator is firm. 3. Check whether the compressor is well, otherwise replace it. 4. Check whether the IPM module is abnormal, otherwise replace it. |

| P3 | over current of outdoor unit | 1. Check whether the ambient temperature exceeds the operation range for the air conditioner 2. Check whether the current detection circuit is abnormal, the electric |

| P4 | temp of module too high | 1. Check whether the pressure is normal when the unit is running, if it is abnormal, should detect the leakage and welding, add refrigerant. 2. Check whether ambient temp. is too high or too low, when the temp. more than -20 degree and less 55 degree, it can disappear automatically. 3. communicate interference, earth wire and communicate wire can’t put in one cable. 4. Check whether temp. switch of compressor is damage, it should be replace if it damaged. |

| P7 | DC voltage abnormal of outdoor unit | 1. Check whether the supply voltage is out of rang from 150 to 270V 2. Check the voltage detection circuit of the IPM base board is abnormal, if it is abnormal, the IPM base board or the electric control board should be replaced. |

| P8 | lack refrigerant or reverse valve fault | 1. Check whether the high and low pressure valves have been opened, otherwise open the valves. 2. Check whether the indoor coil pipe temperature sensor is normal, if it is abnormal, the sensor should be replaced. 3. Check the system pressure is abnormal, if it is abnormal, should detect leakage repairing welding and adding the refrigerant. |

| F6 | outside sensor fault | 1. Check whether the resistance of sensor is normal, otherwise replace it. 2. Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above. 3. When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced |

| FC | outdoor unit drive fault, start compressor failure | 1. Power on again, and check the operation of the compressor is normal. 2. Check whether the connection of the compressor is reliable, otherwise repair. 3. Check whether the components on the electric control board have been damaged, if they are damaged, the components or the electric control board should be replaced. |

Chigo aircon components fault and test methods

Ordinary compressor

Ordinary test (power off)

Testing method: Check the compressor by eyeballing first. If there has burnt vestiges on the surface of compressor or the compressor gives out the bad smell, the reason mainly is that the winding is burnt. If the compressor terminal is burnt, mostly it is caused by the heavy current or the bad contact.

Resistance test

Short circuit: Measure resistance of each winding by universal meter, if the resistance value is lower than the standard, the winding may short circuit.

Open circuit: Measure resistance of each winding by universal meter, if the resistance value is infinite, the compressor winding may open circuit.

Electric leakage & insulation test

Measure resistance between the points of winding and other part of compressor by universal meter, if the resistance value is infinite, means no electric leakage and the insulation is perfect. If the resistance value is tiny or zero, electric leakage may exist in compressor or insulation material may be aged or broken.

AC motor of indoor and outdoor unit

General inspection

Testing method: In the case of non-power,twist motor rotor by hand,meanwhile shaking motor. checking is there any rust,whether blocked.

Fault judgement: If the motor rotor can’t twist, that means the motor blocked. when shaking motor, there should be no abnormal noise, if the noise of inside the motor is small, it means motor shaft loose. If the noise of inside the motor is big, it means there is sundries inside of motor or electrical components loose.

DC resistance

- Turn-to-turn short circuit: measure entire winding resistance by multimet,if the difference between measured value with standard value is larger,it means turn-to-turn short circuit.

- Opencoil: measure entire winding resistance by multimet, if the resistance is ∞,means opencoil.

Electric leakage & insulation test

Measure resistance between the points of winding with other part of motor by universal meter, if the resistance value is infinite, means no electric leakage and the insulation is perfect. If the resistance value is tiny or zero, electric leakage may exist in motor or insulation material may be aged or broken.

General Electric control panel(PCB)

Test method for common electronic component

- SCR: measure resistance between control electrode and positive electrode by multimeter, model Z47 is 20Ω to 400Ω, BT131 is 1.4K ~ 1.7K, if the resistance is too large or too small, means not normal. And if the resistance between other electrode is infinite, means SCR damaged.

- Check the voltage between input terminal and output terminal. If input voltage is ok and did not have the output voltage, need to replace the relay.

- Optocoupler: the red pen connect the first leg of optocoupler, black pen connect the second leg. If the forward Resistance is about 1K,and the resistance between other feet is infinite, means optocoupler damaged.

- Transformer: primary coil resistance is 400Ω~1000Ω, Secondary coil resistance is 15Ω~40Ω,transformer damaged if deviation is big.

- Temperature protective tube, varistor: resistance of protective tube should be 0Ω, that is, resistance of varistor should be infinite.

- Main Chip: check the working voltage (5V) and voltage of reset feet and crystal oscillator, and then check peripheral components Step by step.

- 2003(IC): 2003 is an inverter, in the working condition, input and output potentials are always contrary.

- Diodes: choose “diode” from multimeter, then the red pen connect positive pole, black pen connect negative pole, the resistance should be a few hundred ohm. The reverse resistance is infinity, otherwise diode is bad.

- Transistor: NPN transistor: choose “diode” from multimeter, red pen connect base, black pen connect other two feet and the resistance should be a few hundred ohm, otherwise the transistor damaged. PNP transistor: choose “diode” from ultimeter, black pen connect base, red pen connect other two feet. and the resistance should be a few hundred ohm, otherwise the transistor damaged.

- Infrared Receiver Module: choose “diode” from multimeter, black pen connect power pin, red pen connect other two feet. and the resistance should be a few hundred ohm, otherwise the transistor damaged.

- Crystals: check voltage of crystals. The normal voltage is 2.1 V – 2.5 V, otherwise the crystals damaged.

Charged detection

- Connect PCB with Test-bed. Check mode, wind speed, temperature and so on according to the remote control and control panel. PCB should receive signal accurately and correctly, and indicator light should feedback correctly or check whether has the correct output signal by a multimeter(such as: compressor, fan, four-way valve, electrical heating, step motor, synchronous machine, negative ion, High voltage generator, Dc decelerating motors.)

- Each function control key should be flexible.

- For liquid crystal display or fluorescence display, character should be clear and correct; There should not have the ghosting, brightness blance. Light board display normally, have no obvious Unnormal flicker.

- step motor should be able to rotate.

- For the PCB with self-test function, press the self-test button, and then enter the self-test program. The output should be consistent with the design requirements, no procedures chaos or system halted

Common fault detection

Unit doesn’t work

- Check whether input and output voltage of the transformer is normal (input AC220V, Output AC10V ~ 14V), if no problem, then check the next step.

- Check whether “three-terminal voltage regulator 7805” is normal, if no problem, then check the next step.

- Check whether the voltage of crystal oscillator is normal (2.1V-2.5V), if not, replace crystal.

- If all above are normal, then replace the main chip.

Display bad or indicator light does not shine

Showing bad or light does not shine

- Check whether the voltage of display board is normal (5V).

- Check whether the resistance of display lamp is normal(light-emitting diode forward resistance is a few hundred ohms)

- Check whether chip is cold solder joint, short circuit, or replace the chip.

Buzzer does not ring or abnormal

- Check whether the voltage of Buzzer is normal(about 12V),if normal, then check the next step.

- Check whether the Buzzer is noiselessly.

Not receive or receiving is insensitive

- Check whether the wire of receiver is normal, or replace the connecting wires.

- Check whether the voltage of receiver is normal(5V), or check the power supply circuit.

- Check whether the receiver is normal. If normal, check whether the main chip is normal, otherwise, replace it.

Sensor failure

- Check whether the voltage of room temperature sensor and pipe temperature sensor is normal (make sure at the same temperature conditions, the voltage difference between these two sensors can not be greater than 0.1V, otherwise need to replace).

- Take down the sensor and measure the resistance, its resistance should be within standard deviation.

Indoor fan failure

- Check whether capacitance of fan is the same with nominal value. Or replace the capacitor or check the next step.

- For the tap fan, check voltage of high, medium and low wind relay. The normal voltage is DC12V.

- For the tap fan, check whether the relay is normal or may replace relay.

- Check whether the AC power supply circuit is normal, or replace related devices.

- For the PG fan, check whether SCR (C1815) is cold solder joint, loose, this circuit is normal or not.

- For the PG fan, check whether voltage of SCR (C1815) is normal (Point C is about 0.3V,Point b is about 0.7V ,point e is 0V), or replace the C1815.

Step motor does not run or not good at running

- Check whether solder joint of step motor is cold solder joint, loose and short-circuit for rosin, the main chip, the output voltage of control pin is about 2V,or check whether the main chip is normal or checking the next step.

- Check 4-pin voltage which connect the step motor with 2003 is normal(10 ~ 12V), or check the 2003 or the connecting wire.

- Check whether the connecting wire of step motor and the motor is normal.

The relay does not work

- Check whether the voltage of the relay coil is normal (usually about 12V), otherwise check whether the relays is normal or checking the next step.

- Check whether the relay is good, otherwise replace of relay.

- Check whether the output pin of the main chip is high (5V), or check whether the main chip is normal or checking the next step.

- Check whether the power supply circuit, transformer input and output voltage is normal, or checking the next step.

- Checking whether the piezoresistor and temperature insurance are normal.( the resistance of piezoresistor is infinite. The resistance of temperature Insurance is 0) otherwise, check related components the or checking the next checks

Key is invalid

- Check whether the output pin of the button is normal, or replace.

- Check whether the voltage of display board is 5V, otherwise, check the power supply circuit or connecting wire.

- If all above are normal, check whether the main chip is normal, or replace the main chip.

Electric control panel detection

Red power indicat( LED1) is not bright

- Check whether the LED1 is damaged, if damaged, please replace the diode.

- Check whether the input and output voltage of the 7812 and 7805 is normal (7812 input 14V, output is about 12V,7805 input 12V, the output 5V), if damaged, replace the related device or check downward.

- Check whether the bridge rectifier diodes D1-D4 is normal, if the damaged, please replace related diode.

- Check whether the power supply transformer of input and output is normal (input is about AC220V, the output is about AC14V), if it is damaged, replace the transformer.

Green light LED2 does not shine or the phase sequence protection

- Check whether the light-emitting diode LED2 damaged, if not normal, then the replace the light-emitting diode.

- Check whether the Q5 (9014) collector voltage is normal, if not normal, then the replace 9014.

- Check whether the relay RY3 is normal, if not normal, then the replace the relay.

- Check whether the resistance of the R7-R10 is normal, if not normal, then the replace the related resistance.

- Check whether the phase sequence of the three-phase power supply is normal, if not, then the replace phase sequence.

No-voltage for over-current detection circuit

- Check whether the rectifier diodes D5-D8 is normal, if not normal, replace related diode.

- Check whether the current transformator L1 is normal, if abnormal, replace it.

Over-current protection too long or too short

Check whether capacity of capacitance E3, E6 is normal (the normal over-current protection is about 20s ~35s), replace if it is not normal.

Appear over-current protection

- Check whether the integrated block LM311 (7) feet IC3 is normal, if not normal, check IC3. If damage, replace it.

- Check whether triode 9012 is normal. If abnormal, replace it.

- Check the voltage of over-current relay coil is normal (about12V), if it normal, check whether the relay damage.

No defrost signal temperature signal

- Check whether the temperature sensor is normal(measure sensor resistance), if the resistance is too large or too small or even infinite, or 0Ω, then replace sensor.

- Check whether the voltage of the defrost relay coil is normal(about 12V), if it’s normal, check whether the relay damage.

Capacitor

Appearance inspection

Testing method: Visual inspection whether the appearance of capacitor expansion, burst. If it was, that means the capacitor fail.

Check by open circuit

Testing method: Check the capacitance by multimeter, If the pointer could swing to the right at once, then the pointer slowly reset to 0. That means the capacitance is no problem. If the pointer does not 26 move or do not reset, means capacitance is open circuit, electrolyte dry, or short-circuit.

Capacitance breakdown, leakage of electricity

Testing method: Check the capacitance by multimeter. If the pointer could then the pointer can’t move. That means the capacitance is breakdown or leakage of electricity.

Loss tangent inspection

Judge standard: run about 10 minutes, check surface temperature of capacitance. If the surface temperature exceeds the ambient temperature about 15 ℃,that means loss tangent has exceeded the limit value 0.0018.

Check capacitance

Check by pointer type multimeter: if the pointer oscillation amplitude is bigger than the standard capacitance, that means capacitance has been attenuated. Digital Multimeter: check by Cx interface, the capacity should not exceed the nominal capacity

of ± 5%.

Insulation inspection

Testing method: normally, the resistance of capacitance is ∞, if the number of resistance is thousands of ohms or greater, that means capacitance is no problem. If the resistance is smaller or 0, that means capacitance has been damaged, should be immediately replaced.

Transformer

Visual inspection

Check whether the appearance of transformer burnt phenomenon, check whether has the burnt transformer smell. If the appearance of burnt yellow phenomena or had burnt smell, transformer winding is bad.

Check on running

Testing method: make transformer running under load (which can run with PCB),should be running smoothly, there shouldn’t be unusual noise. if there is unusual noise, it is multi-electromagnetic noise.

Electrical Characteristics

- No-load characteristics : As for the power supply 220V/50Hz, 220V/60Hz, 240V/50 Hz, power 5 ~ 8W transformer primary load current ≤ 20mA; power supply 115/60Hz; power 5 ~ 8W of the transformer primary No-load current ≤ 35 mA; no-load output voltage does not exceed rated voltage +10%.

- Load Characteristics : transformer at rated load conditions; the error of the secondary coil voltage should not be greater than the requirements.

Output power

- Measured current and voltage with the multimeter, and then according to P = UI, the output power should not exceed transformer nominal requirements of ± 8%, If you exceed this requirement, you can determine the transformer’s power attenuation.

- According to P=U2/R, the output power shall not exceed the transformer nominal requirements of ± 8%, If you exceed this requirement, you can determine the transformer power attenuation.

DCR

- turn-to-turn short circuit: check by multimeter, select the appropriate range, measure the resistance of transformer winding, if the deviation between real resistance with the standard resistance is great, that means the inter-turn short circuit and outlet the open circuit.

- Coil Open circuit: check by multimeter, select the appropriate range, measure the resistance. If the resistance is ∞, that means transformer coil open circuit or open circuit.

Insulation inspection

Insulating property between the shell and the iron core

Testing method: check by multimeter, select the appropriate range, measure the resistance. If the resistance is

∞or tens of thousands of ohms, means insulating property is good. If the measured resistance of the smaller or 0,means core screen has been destroyed.

Insulation between the windings

Testing method: check by multimeter, select the appropriate range. one pen contacts with the transformer primary, the other contacts with secondary output transformer. If the resistance is ∞ or tens of thousands of ohms, means insulating property is good. If the measured resistance of the smaller or 0,means core screen has been destroyed.

Four-way valve

General inspection

Visual inspection: pull coil of each power cord, wires should be no break phenomenon.

DCR

- Turn-to-turn short circuit: Check by multimeter, select the appropriate range, measure the resistance. If the resistance smaller than the standard resistance.it means four-way valve turn-to-turn short circuit.

- Coil Open circuit: Check by multimeter, select the appropriate range, measure the resistance. If the resistance is ∞, it means four-way valve open circuit

Insulating property

Testing method: check by multimeter, select the appropriate range. one pen contacts with input terminal, the other contacts with body. If the resistance is ∞ or tens of thousands of ohms, means insulating property is good. If the measured resistance of the smaller or 0,means core screen has been destroyed.

Run on power

Testing method: connect the four-way valve and the electrical components, connected to rated power; change the mode between cooling and heating mode, check whether the four-way valve could correctly change.

Fault judgement: if the four-way valve could not change correctly, means four-way valve bad or wire partial short-circuit fault.

Step motor

General inspection

Visual inspection: check whether the appearance of step motor is burnt, rust. If have, that means the winding of motor is broken. In the case of non-power, hand knob step motor’s output shaft, if there exist strange noise, that may be caused by driving wheel not matching or loose for connecting piece.

Check torque

Self-positioning Torque: under the action of this torque, step motor should not lose, not jitter, non-skid.

Resistance test

- short circuit: Measure resistance of each winding by universal meter, if the resistance value is lower than the standard, the winding may short circuit.

- open circuit: Measure resistance of each winding by universal meter, if the resistance value is infinite, the compressor winding may open circuit.

Check on running

Testing method: make sure step motor running with load, there shouldn’t be unusual noise. if there is unusual noise, it is caused by rust or wear. If the step motor does not work, most is due to open coil, short circuit, or rust.

Insulating property

Testing method: check by multimeter, select the appropriate range. one pen contacts with input terminal, the other contacts with body of step motor. If the resistance is ∞ or tens of thousands of ohms, means insulating property is good. If the measured resistance of the smaller or 0, means core screen has been destroyed.

Electrical performance checking

Testing method: use needle nose pliers or similar tool clamp output shaft of the motor, rotate it clockwise.at the same time, choose AC 20V voltage, then connect two pens with step motor input end. After rotating the output shaft there should be clear voltage shows on multimeter.

Synchronous motor

General inspection

Testing method: Visual inspection: check whether the appearance of synchronous machine is burnt, rust. If have, that means the winding of motor is broken. In the case of non-power, hand knob output shaft, if there exist strange noise, that may be caused by driving wheel not matching or loose for connecting piece.

Resistance test

- short circuit: Measure resistance of each winding by universal meter, if the resistance value is lower than the standard, the winding may short circuit.

- open circuit: Measure resistance of each winding by universal meter, if the resistance value is infinite, the compressor winding may open circuit.

Testing method

Check by multimeter, select the appropriate range. one pen contacts with input terminal, the other contacts with body of step motor. If the resistance is ∞ or tens of thousands of ohms, means insulating property is good. If the measured resistance of the smaller or 0, means core screen has been destroyed.

Check on running

Testing method: make sure synchronous machine running with load, there shouldn’t be unusual noise. If there is unusual noise, it is caused by rust or wear. If it does not work, most is due to open coil, short circuit, or rust.

Torque checking

Testing method: make sure the motor running by rated power, use needle nose pliers or similar tool clamp output shaft of the motor till making the motor stop.

Fault judgement: At rated voltage, frequency, braking torque of synchronous machine should be ≥ 0.345Nm, if the output shaft of the torque is less than 0.345Nm, can be found the torque is not enough, can not bring the throttle to run.

Electrical performance checking

Testing method: use needle nose pliers or similar tool clamp output shaft of the motor, rotate it clockwise.at the same time, choose AC 20V voltage, then connect two pens with step motor input end. After rotating the output shaft there should be clear voltage shows on multimeter.

Outdoor electrical heating cable and crankshaft electric heating cable

- Outdoor electrical heating cable is controlled by the outdoor environment temperature: Starts below 0 degree, closes after the temperature up to 3 degree. As long as the machine is with electricity connected, the outdoor electrical heating cable will keep to determine whether it is needed to work or not.

- Crankshaft electric heating cable is controlled by the outdoor environment temperature: Starts below 0 degree, closes after the temperature up to 3 degree. As long as the machine is with electricity connected, the crankshaft electrical heating cable will determine whether it is needed to work or not.

- When in test mode, the outdoor electrical heating cable and crankshaft electrical heating cable will not start.

Chigo aircon troubleshooting

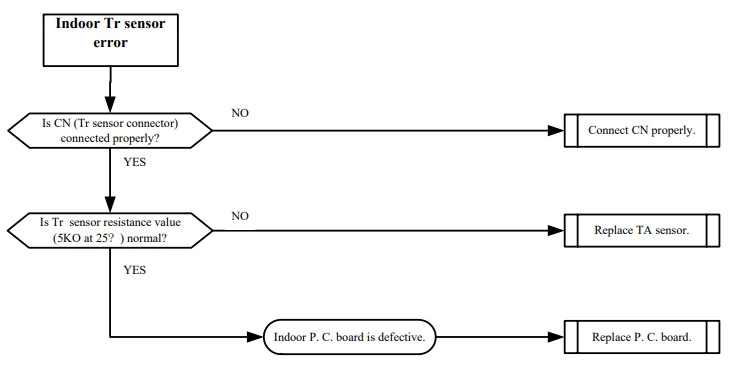

Indoor Tr sensor error

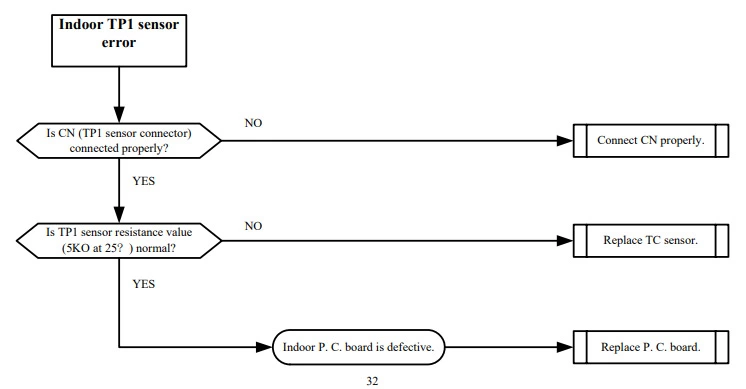

Indoor TP1 sensor error

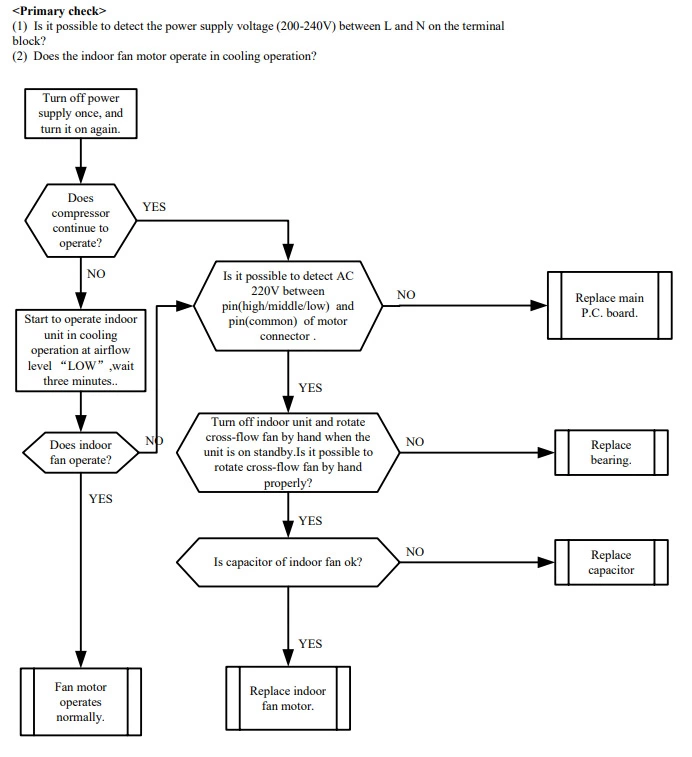

Only indoor fan motor does not operate

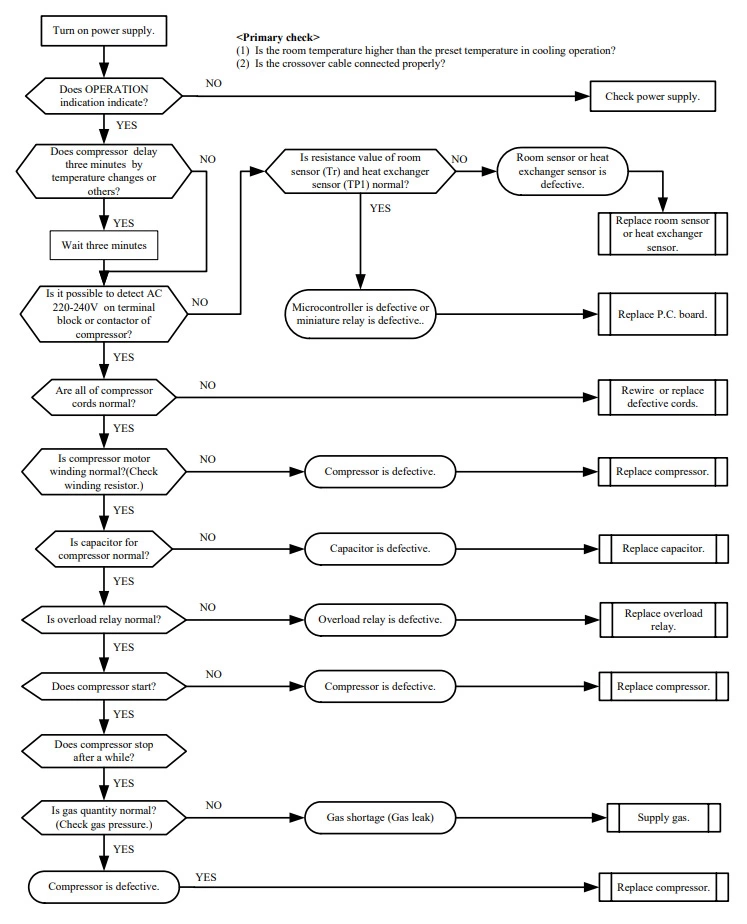

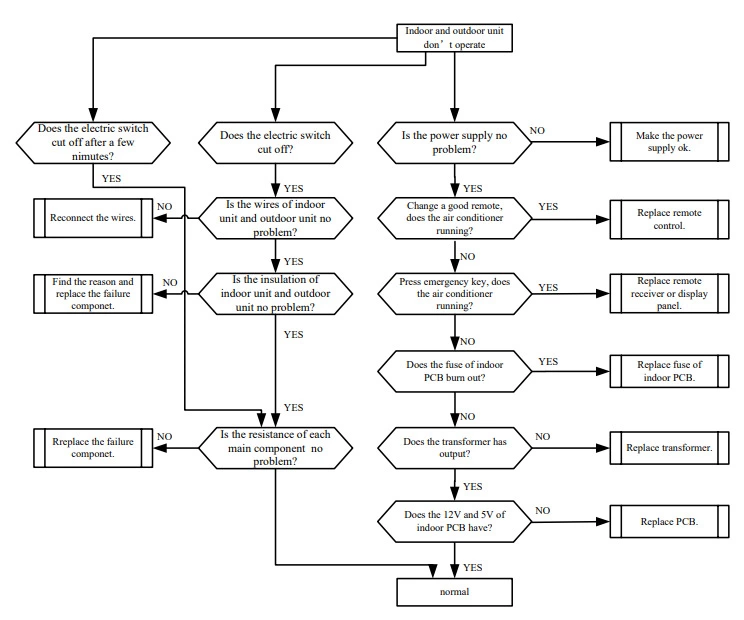

Indoor unit and outdoor unit don’t operate

Compressor does not operate