People living in hot areas probably know about air conditioners, but they do not know about the evaporator and condenser coils. The working of your inner AC may be unknown to you, but after learning this article, you will know how your AC works and does the cooling job. You will also be able to know which kind of evaporator coil you should use.

It is essential to know about the size and routine maintenance of your evaporator coil you need to get better cooling of your air conditioner and make it work efficiently. Air Conditioners do not actually produce heat like a furnace in heaters but use refrigerants to absorb heat from the air and take hot air outside. It is also known as the Evaporator core.

It is located inside the air handler where the bowler fan is present. Copper, steel, or aluminum make the Evaporator coil. Why copper pipes are used in air conditioners? The main reason is copper is one of the best conductor of heat. Most of the AC consists of bent U-shaped tubes, but it is difficult to determine the evaporator coil size.

There are several heat pumps and evaporator coils available in the market. Determine which is best for you is a difficult task. We will tell you the complete details about different kinds of evaporator coils and their advantages and disadvantages.

Fins in radiator style

These fins help maximize the heated area so heat cannot be gathered and heat dispersed.

Tubes are of copper and aluminum

They are attached to the back of the coil. Fin assembly. They take the refrigerant indoor and outdoor coil.

Refrigerant

The compressor circulates it. It absorbs inside heat and takes it outside.

Sizes

If you want a coil for residential use, you need a coil from 1 -ton heating/cooling capacity to 5 tons of capacity. Its size should be equal to the size of the condensing unit outdoors. An evaporator pump decreases the temperature. A large evaporator coil is used to cool the significant places.

Shapes of Coil

The most common and most frequent coil use is A-coil. This is produced by standard industry and in use of all brands. A lot of brands use z coils and N coils. They are used in compact AC designs and many others.

Types of evaporator coils

A-Coils

A lot of brands manufacture A-Coils. They are in use of outstanding AC brands. The shape of these coils is similar to the shape of A. Two slanted coils are attached to the top. The refrigerant tube is present inside the A shape. These tubes run in both ways. Their use is to gather the heat in AC mode. As a result, coil fins get very cool. Moisture naturally appears on the coil to flow down and fill the pan. The water moves into the pan to the floor and leads it outside the house. There are razor fins available. They are used to create a huge amount of surface space. This space is used for a gathering of heat. A metal sheet manufactures the screws present on the lower right and lowers left side. If you want to clean it, remove these screws. This will help you to get access to the dirtiest part of the evaporator.

Advantages of A-coil

These coils are reliable, and you can clean them easily. They are easily available. They are manufactured by third–party and used by all well-known brands. They are made of the best parts and quality than others if you want to repair the coil using the brand or technician with a better record.

N or Z Coils

You call this coil N or Z because it depends on the way you install the coil. It does not matter the furnace is horizontal or vertical. Their shape and design are similar to zig zag, so some technics called them zig zag coils. They are not common as A coils but are used by a few brands.

Advantages and disadvantages of N or Z coils.

Most of the HVAC believes that Nor Z coils are more efficient than A coils. If they have more fins, the surface area will be more, so they have a greater ability to gather and disperse heat. They are more compact coils.

The disadvantage of this coil is that they are harder to clean because of their complicated design. If the dirt remains inside, it will decrease the efficiency of a coil which may disturb the AC system. The other disadvantage is that due to its compact design. They freeze up too high. He gets very cold during the AC cycle.

Slab Coils

These coils are not commonly used but still have their place. This performance is almost the same. The refrigerant tubes are present inside the slabs. These coils are most commonly used in air handlers and furnaces.

Advantages and disadvantages of Slab Coils.

These are compact designs, so they gain less space. They are also easy to clean. The disadvantage of this coil is that the surface space present in these coils is less, so they work less efficiently.

Goodman Aluma Fin 7 Coil

Goodman now became a Daikin brand. Daikin is a well-known air conditioner brand. It has very improved quality and usually focuses on presenting new things. Alumafin 7 is the A-coil. It improves the heat transfer process. Several features of this coil make a difference. They have 7mm to 9 .5mm refrigerant lines. It is proved that they have greater refrigerant lines, so they create more surface space and show better efficiency.

Cased and uncased coils

Some coils come in the cased form and some in uncased form. They have their cabinet. They are mostly used in air handlers and furnace installation. Uncased coils are mostly placed inside the cabinet of the air handler furnace.

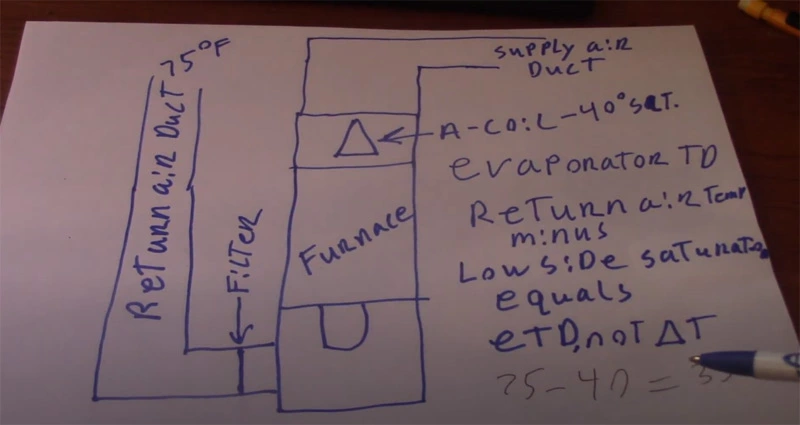

How to calculate evaporator coil capacity

It is not difficult to do evaporator coil capacity calculation. The complete details are given below.

Larger Evaporators are used to cool large areas. Professionals called the size in tons. Its power is equal to 12000 British Thermal units per hour. You can calculate the size with the temperature range. You have to subtract the outgoing evaporator temperature if you want to put water into the evaporator at 60 degrees. Fahrenheit and subtract with 46 degrees Fahrenheit. 60-46=18

Now you have to multiply the answer with volumetric flow rate. It is measured in gallons per minute. 14*400= 5600.Multiply this answer with 500 5600*500 = 2,800,000.This is the equator size measured in BTUs per hour. Now divide this answer by 12,000, 2,800,000/12000

This is the correct value of evaporator size in tons. The evaporating coil sizing chart is very complicated to understand. If you learn the calculation, it is easy to understand.

Why the cleaning of the evaporator coil is important?

It is very crucial to maintain the cleaning of your evaporator coil. Dirty coils use more energy and damage pure AC units. Thet also decreases the efficiency of your unit. You have to keep your coil clean for better performance of your AC unit. You have to change your air filter once a month. Try to keep maintenance of HVAC once or twice a year. They properly inspect your coil and maintain its cleaning. It is the fundamental component of your AC unit that absorbs heat from your home, so its maintenance is essential. It works with the condenser coil to exchange the heating process.

Conclusion

The types mentioned above of evaporator coils have outstanding styles and benefits. You only need to select the coil whose size matches your requirement. If the space is big, you need a large evaporating coil, and if the space is small, you need a small evaporating coil. It depends on your need and place. You should keep in mind that the condenser and evaporating coil must have the same size because they both work in the same way.

Suppose the air from the vent will be warm its means that you need to replace it. You need to maintain it properly for better energy usage and utility control because dirty coil increases the energy use. It is the place where cooling happens in the AC. It assists in keeping your home cool and comfortable in hot summers, so take care of its size and maintenance. It will help to do its job properly and efficiently, and safely.

You may also be interested to learn will a 2000 watt generator run a 5000 btu air conditioner.